Ship building has undergone significant advancements over the years, driven by innovation, technology, and the pursuit of efficiency and sustainability. From novel materials to innovative design concepts, several incredible innovations have changed the maritime industry and reshaped the way ships are built.

3D printing technology:

3D printing, also known as additive manufacturing, has emerged as a game-changing innovation in Abu Dhabi ship building. This technology allows ship builders to create complex components and parts with unprecedented precision and efficiency. From intricate hull structures to custom fittings and fixtures, 3D printing allows the rapid prototyping and production of ship components, reducing lead times and material waste while offering design flexibility and customization options.

Lightweight composite materials:

The adoption of lightweight composite materials such as carbon fiber, fiberglass, and advanced polymers has changed ship construction by offering superior strength-to-weight ratios and corrosion resistance compared to traditional materials like steel and aluminum. These lightweight materials allow the construction of lighter and more fuel-efficient vessels, reducing operating costs and environmental impact while improving performance and longevity.

Advanced simulation and modeling:

The use of advanced simulation and modeling techniques, such as computational fluid dynamics (CFD) and finite element analysis (FEA), has changed the ship design and optimization process. By simulating fluid flow, structural loads, and other environmental factors, ship builders can optimize hull shapes, propulsion systems, and operational parameters to increase efficiency, stability, and seaworthiness while minimizing fuel consumption and emissions.

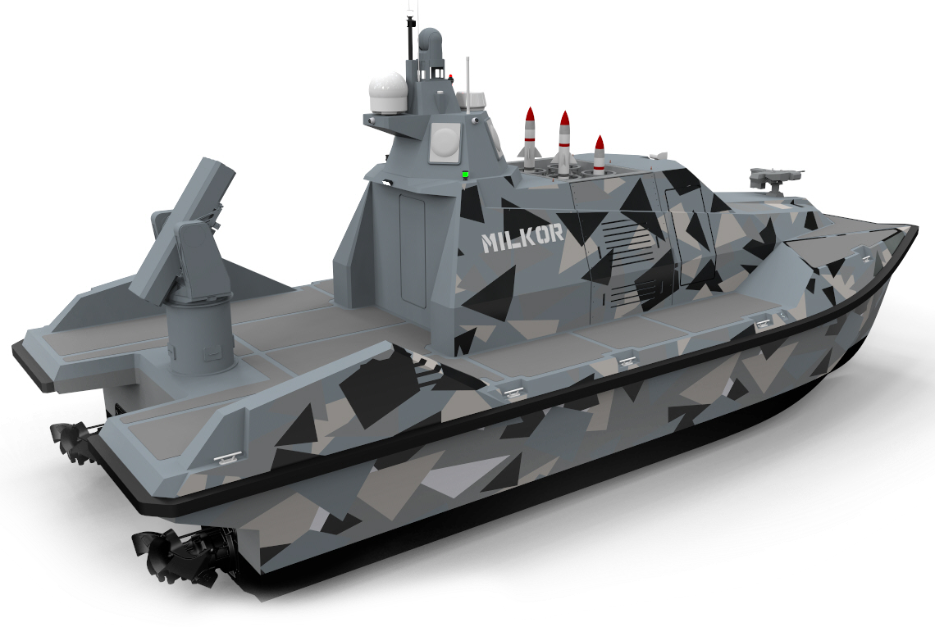

Autonomous and unmanned systems:

The integration of autonomous and unmanned systems into ship building and operations represents a groundbreaking innovation with the strength to change the maritime industry. From autonomous robotic welders and 3D printers to unmanned surface vessels (USVs) and autonomous underwater vehicles (AUVs), these systems offer opportunities to improve productivity, safety, and cost-effectiveness in ship construction, maintenance, and operations.

Green technologies and sustainable practices:

In response to growing environmental concerns and regulatory pressures, ship builders are increasingly embracing green technologies and sustainable practices to reduce the environmental footprint of maritime construction and operations. Innovations such as hybrid propulsion systems, LNG-fueled engines, solar panels, and wind-assisted propulsion technologies allow the construction of eco-friendly and energy-efficient vessels that comply with stringent environmental standards and emission regulations.